It’s been 22 years since the Tour de France was won on a steel bike. But because of the great advances made in recent years, might we see steel overcome carbon in the world’s greatest bike race soon? For many it would hark back to a romantic and nostalgic era of the likes of Hinault and Merckx winning great races on elegant, beautiful bikes that offered both comfort and durability. Sam Lawson of Genesis Bikes thinks that, “We’re not a million miles off.”

While carbon fibre has been the dominant material used by professionals for the last two decades, steel always held a special place in the hearts of many a rider. Let’s face it, the aesthetics of a steel bike give it a much classier look than a carbon one. And in terms of ride quality, many cyclists talk of a springy, responsive and indulgent character with a bit of zing and life to it.

Steel also gives you a wide choice, even more so now that hundreds of independent frame builders are making the most of a resurgent cycling population looking for something distinctive and original. It remains an adaptable and easy material to work with to achieve that. Progress in steel technology, developed in no small measure by the likes of Reynolds and Columbus, means that a steel frame no longer carries the weight it used to.

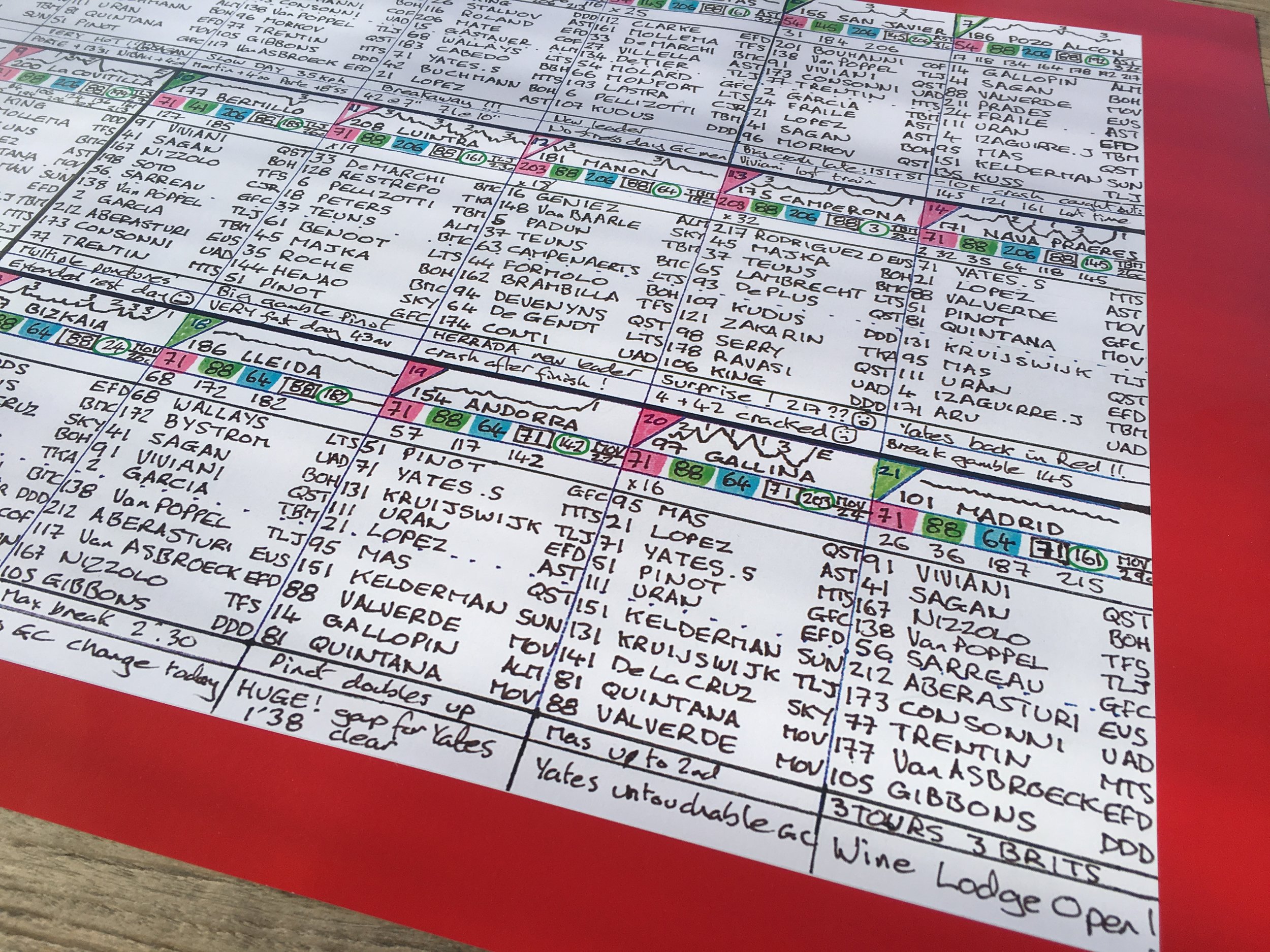

Independent frame builders like Rusby offer distinctive looks and styling

Establishing a patent way back in 1898, Reynolds made tubing for Spitfires, cars and speed skaters using different types of steel. But it’s bike tubing where they have been at the forefront, forging a global name for themselves as they produced the lightest and stiffest frames. Since that time they have increased the strength of their tubes by a factor of four and reduced the weight of a round tube by 40%. But it’s three numbers: 953, that mean the likes of Genesis are now able to produce a high performance bike with a frame that dips under 1.5kg.

It was the original Reynolds 531 tubing that produced the most Tour de France winners, so named because it had a tensile strength of around 53 tons per square inch (tsi). 753 followed, the world’s first heat-treated steel for cycle use (around 75tsi). Then along came 853 (83tsi). But it’s now 953 (which should in fact be called 1053 for its 105tsi) that is the most advanced steel tubing available. The metal is double vacuum-melted to achieve purity levels that match aerospace applications.

Rourke Cycles in Staffordshire offer 953 as an option for their custom builds. Their master framebuilder, Jason Rourke, reckons that, “In a world of marginal gains, steel can make the difference between victory and disappointment. In all honesty, 953 is technologically more advanced than most carbons out there, and is the major turning point when it comes to steel high performance cycling.”

Rourke recently provided a track bike for Olympic cyclist Elinor Barker. “It’s really light, very strong and ultra responsive, so we hope it’ll serve her well. Most track racers have grown up with a stock carbon bike and have never realised how fantastic a steel frame can be. As far as I’m concerned steel is still the best and I can’t wait to see her reaction as she races on it for the first time."

Elinor Barker with her steel track bike

Taylor Gunman rides for Madison Genesis and his team bike is a Genesis Volare 953. A former New Zealand national champion, he says he loves the ride quality of his team issue steel bike. “These bikes are strong, durable and they ride fast.” It’s particularly well suited to criterium circuit races and some of the rougher surfaces he has to confront on the continent. He said it came into its own riding the gravelly terrain as he grappled with muddy corners and rolled over cobbles at Dwars door het Hageland in Belgium. “I sat comfortably on my performance-steel bike while all around me they wrestled carbon.”

Teammate, Gruff Lewis agrees, saying that when he first started racing on steel other riders would look surprised, even dismissive. “I think a lot of them are now genuinely jealous of this bike, and its comfort, performance and looks.”

The Genesis Volare 953

While the Volare is half a kilo or so heavier than some of the carbon models favoured by the majority of the peloton, that’s only the equivalent of a filled water bottle. When you take into account its comfort, rigidity and responsiveness, that’s not a very high price to pay. While it’s possible to produce lighter carbon frames, they will always be restricted by the UCI rules stating that the whole bike must weigh a minimum of 6.8 kg.

While the Volare is ideal for criteriums and cobbles, Genesis accept that it’s not quite up to the mark when it comes to riding one for a grand tour just yet. But as the development of steel tubing technology continues apace, it could only be within five to ten years that we see a Tour de France winner on a steel bike. That really would be a great comeback story!